CHILLER COOLING TOWER

Cooling Tower

Solve frequent cooling tower issues

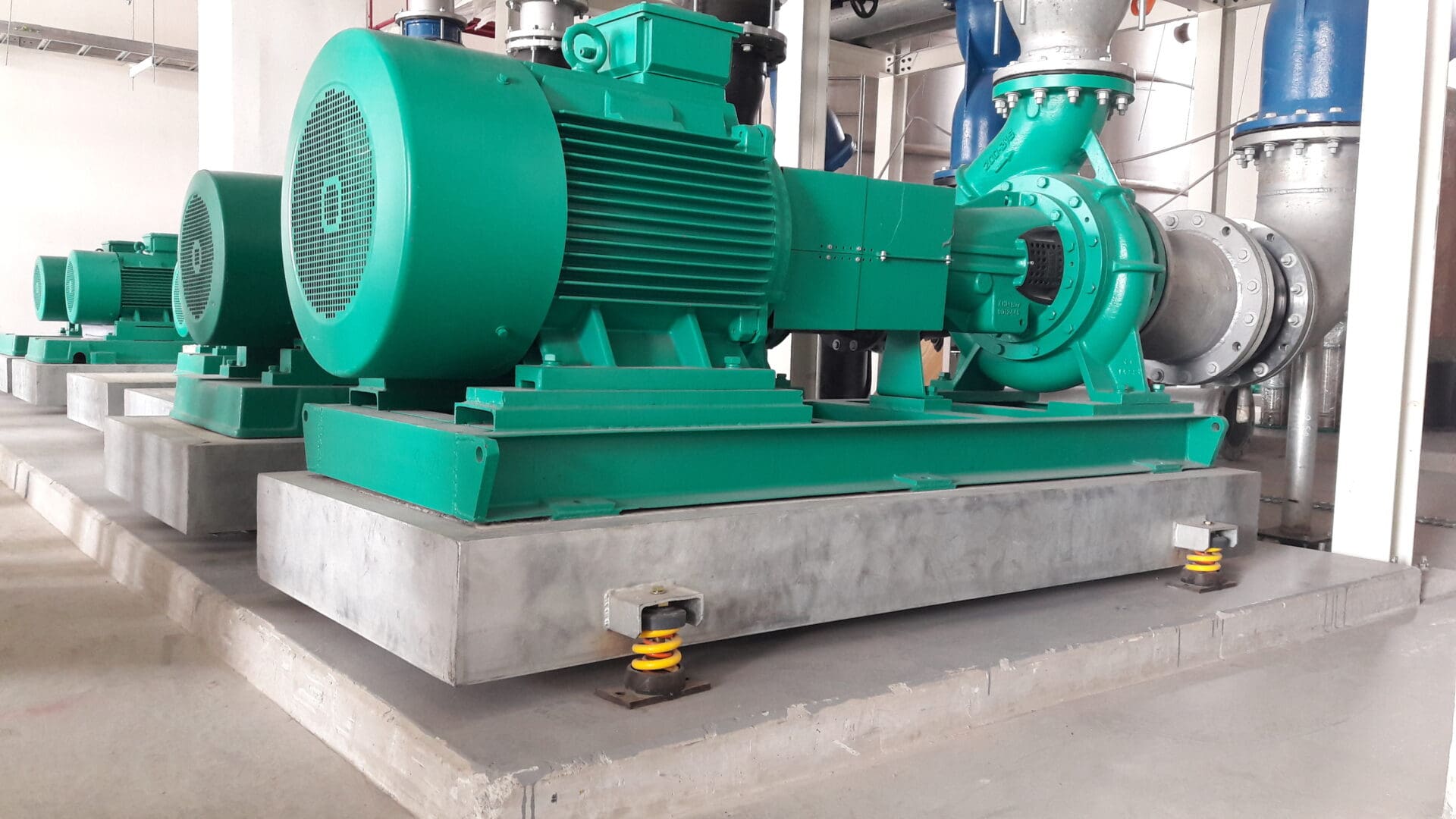

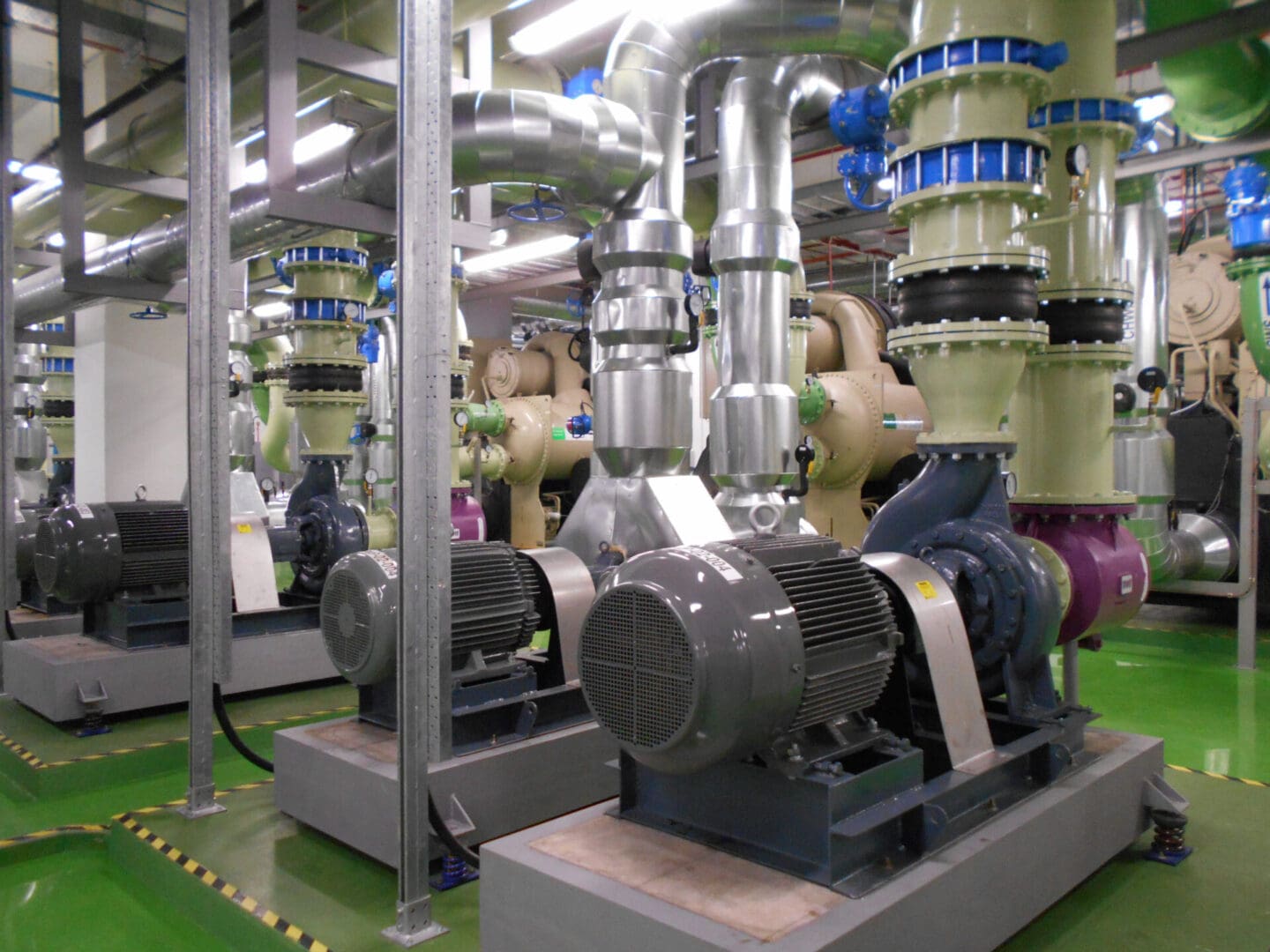

Cooling towers are massive heat exchangers that are used to cool massive structures and remove heat generated by industrial or massive mechanical action. Water evaporation is used in these towers to remove any surplus heat generated during the operation. In any case, cooling towers might face a variety of challenges that can result in inefficient cooling or even injury. Users should be aware of the issues that can arise with cooling towers, particularly concerns related to the treatment of the water in the cooling towers, to avoid costly fixes and substitutions.

Warming and ventilation tower systems, which use cooling towers to remove heat from massive structures involved in industrial activity, are found in every industry. Despite this, a few general difficulties may arise during the process. As a result, it's vital to understand what to pay special attention to save time and money in the long run.

Regulations and standards aimed at improving water efficiency and lowering costs suggest that cooling towers should be operating as efficiently as possible. There are a few things that need to be given special attention to keep your cooling tower system in top working order. This will help you understand common cooling tower concerns and configurations so you can improve the performance of your cooling tower water treatment.

This article discusses common cooling tower water treatment challenges and how a cooling tower water treatment specialist may help you solve them.

MINERALS ACCUMULATION IN THE COOLING TOWER

Mineral collection/deposition is one of the challenges that most natural draught cooling towers face. The condition caused by the accumulation of minerals in the water, such as calcium phosphate, magnesium silicate, and iron oxide, is known as collection. Because the accumulation affects the principal piece of the cooling tower, heat move execution is reduced. If the buildup is ignored, it can result in significant energy expenses for the cooling tower's operation, as well as the need to repair and upgrade the complete cooling tower system.

Solution: Cleaning the towers regularly and reducing the volume of a mineral collection are the most efficient ways to prevent mineral aggregation.

HIGH BLOWDOWN MEASURE

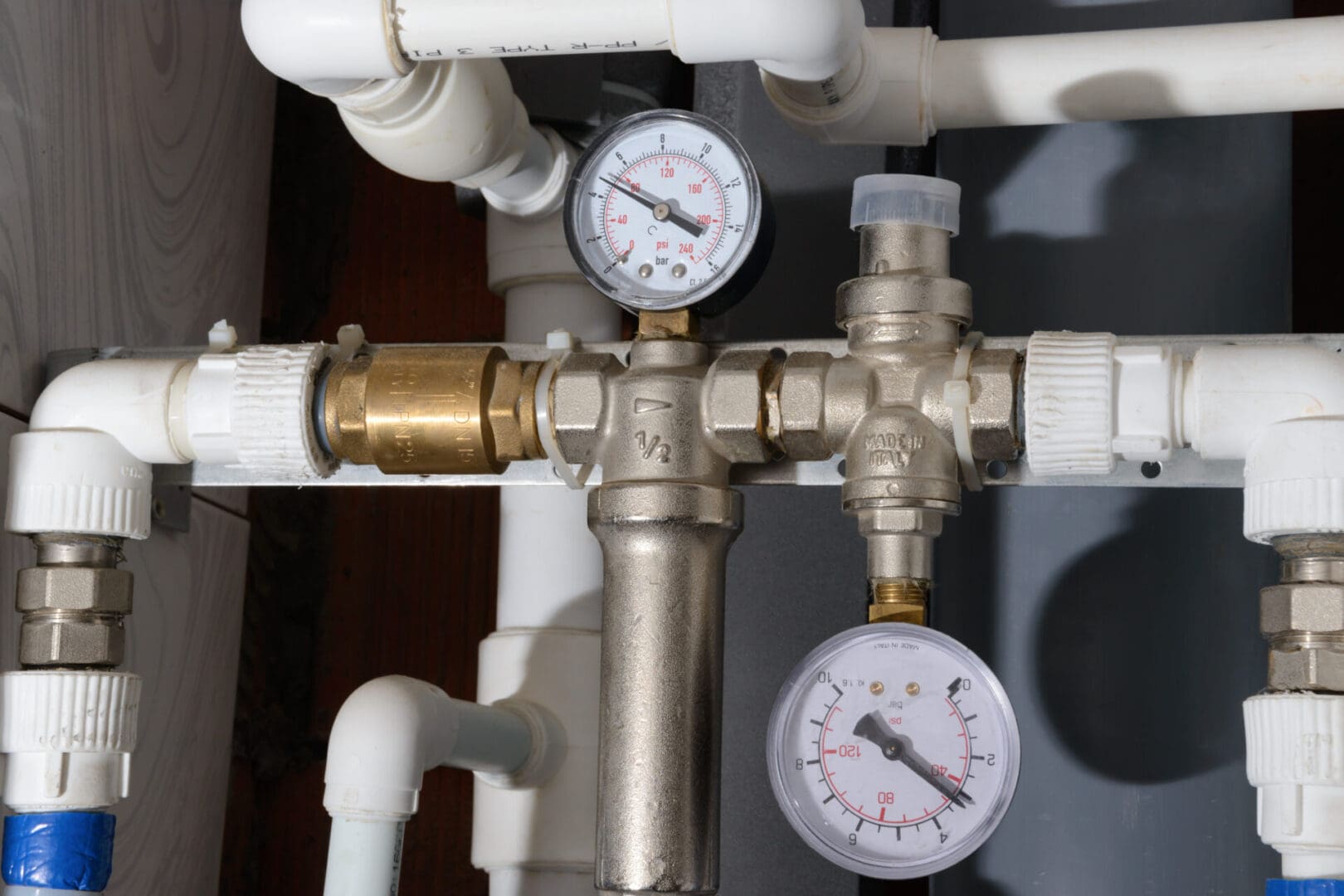

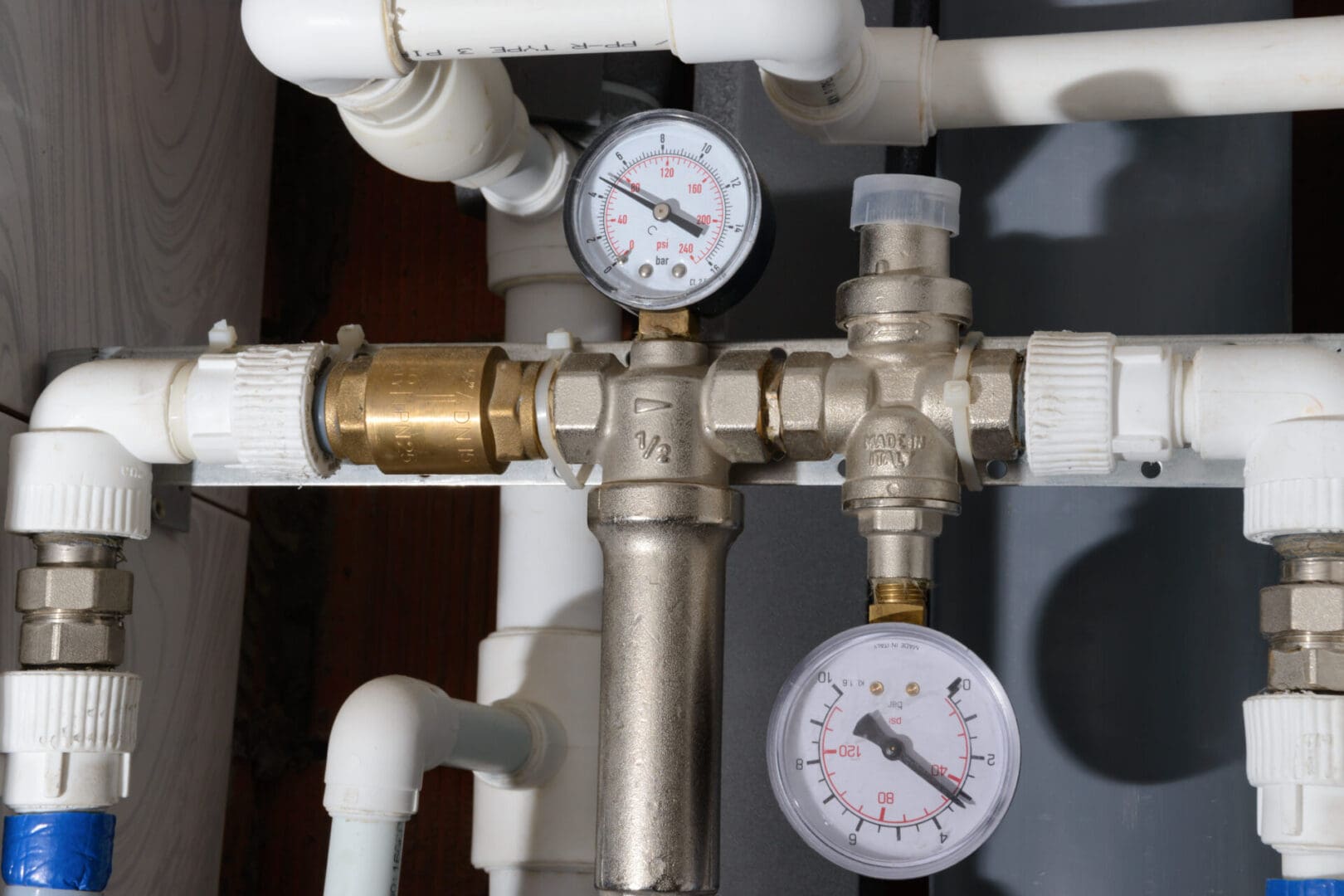

Evaporation is used to remove surplus heat from cooling towers, and bunches of water are used to make up for any deficiency. Strong stores can stay in the cooling tower because cosmetics water is fed to the cooling tower. This increases the need for a "blowdown," which removes solid waste and breaks up solid development to prevent gear scaling or erosion. When blowdown occurs, a large amount of course water is lost along with the strong waste, therefore it's critical to keep an eye on this.

Solution: If your cooling towers demand a higher-than-average amount of blowdown, you should invest in a productive cooling tower water treatment system. Depending on the situation, there are several options for preventing an abundance of cooling tower blowdowns:

Filtration of water

Filtration on the side of the stream

Eliminate scale framing and contamination-causing consumption to keep up with the nature of cosmetics water.

CONTAMINATION OF ORGANIC RESOURCES

If you notice that a cooling tower has been contaminated by organic growth, you must immediately conduct a water test. The pollution poses a threat to the health of those who live in and around the structure, as foreign substances can contaminate the air. The water is treated by combining the tower system with chlorine over 48 hours in various conditions, then flushing and topping off with fresh water.

Solution: To prevent future contamination, all holes in the cooling water tower system should be filled. The chlorination of the water and examination of Pneumohphila should be performed. To avoid needless cooling tower replacements, businesses should only hire competent cooling tower service staff.

tower for cooling

CANCER FOR YOUR COOLING TOWER: EROSION

Water eats and disintegrates nearly anything in the globe over time, yet water isn't the predominant component when eroded in planned FRP circular cooling towers. While it is undeniable that water is a device that facilitates the entry of damaging specialists, the actual experts are far more serious than the effects of water. Throughout their lifetime, many programmable cooling towers become fragile and defenceless to newer synthetics. Consumption is a major worry because it can limit the tower's activity and results, increase energy expenses, and in certain cases harm the hardware inside the tower.

The proposed solution for preventing erosion is to clean the towers regularly. Furthermore, picking cooling tower components and synthetic materials that are generally erosion-resistant, such as fibre-built-up plastic, is an excellent way to combat cooling tower part corrosion.

LOW CONCENTRATION CYCLE

CoC is used in cooling towers to determine how much accumulation development is present in cooling tower water vs the proportion of cosmetics water. Because of the higher pattern of fixation, there is less need for cosmetics water and blowdown, resulting in water and cost savings. The ideal proportion is three to six fixation patterns, which is three to six times the grouping of stores in the water cycle than the cosmetics water. Water usage can quickly increase in tower systems with a low pattern of fixation, requiring greater investment.

Solution: The nature of the water cycle, cosmetics water, and the type of cooling tower being used in many water treatment tower systems will direct the important medicines to achieve the optimal pattern of fixation for your workplace. Nonetheless, there are a few arrangements that can help:

A water treatment tower system provides better cooling tower control.

Checking conductivity and limiting blowdown

Controlling pH and alkalinity to prevent scale formation

Feed hardness, iron, and silica levels are decreasing.

Monitoring the growth of microorganisms